Understanding Fuse Resistors: An In-Depth Guide

I. Introduction

In the world of electrical engineering, safety and reliability are paramount. One component that plays a crucial role in ensuring these qualities is the fuse resistor. This article aims to provide a comprehensive understanding of fuse resistors, their functions, types, applications, advantages, limitations, and future trends. By the end, readers will appreciate the significance of fuse resistors in electrical circuits and their impact on various industries.

II. The Basics of Fuse Resistors

A. What is a Fuse Resistor?

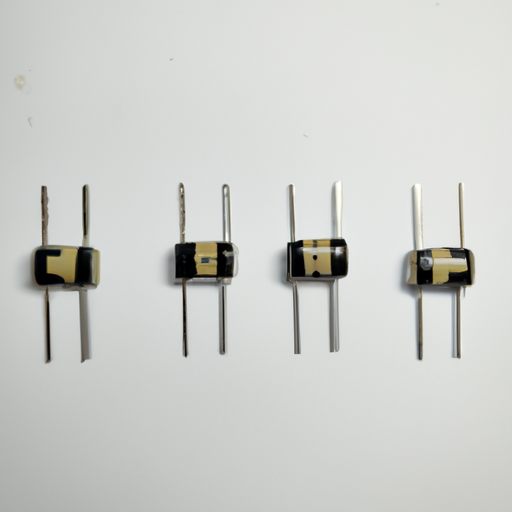

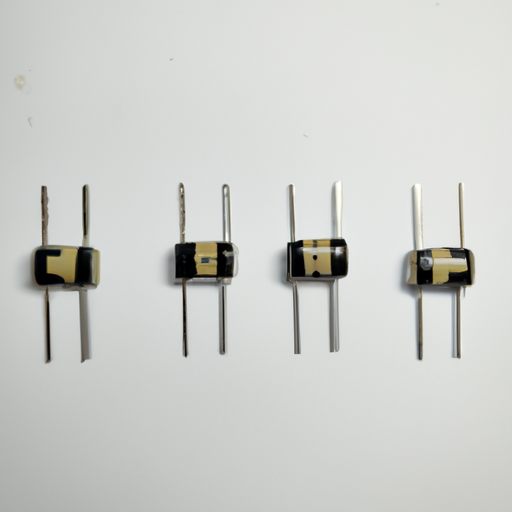

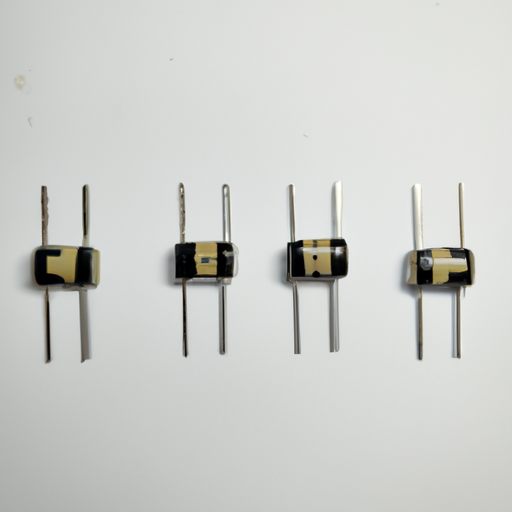

A fuse resistor is a specialized component that combines the functions of a resistor and a fuse. It is designed to limit current flow while also providing overcurrent protection. When the current exceeds a predetermined level, the fuse resistor will "blow," interrupting the circuit and preventing damage to other components.

1. Definition and Function

The primary function of a fuse resistor is to protect sensitive electronic components from excessive current. Unlike traditional fuses, which only serve to interrupt current flow, fuse resistors also provide resistance, allowing them to dissipate heat and manage power levels effectively.

2. Components of a Fuse Resistor

A typical fuse resistor consists of a resistive element, which can be made from various materials, and a protective casing. The resistive element is designed to handle specific current ratings and thermal conditions, while the casing ensures durability and safety.

B. How Fuse Resistors Work

1. The Principle of Operation

Fuse resistors operate on the principle of thermal overload. When the current flowing through the resistor exceeds its rated capacity, the heat generated causes the resistive element to melt or break, effectively interrupting the circuit. This self-resetting feature is what sets fuse resistors apart from traditional fuses.

2. Comparison with Traditional Fuses

Traditional fuses are designed solely to interrupt current flow when it exceeds a certain level. While effective, they do not provide any resistance, which can lead to voltage spikes and potential damage to connected components. Fuse resistors, on the other hand, offer both current limiting and overcurrent protection, making them a more versatile choice in many applications.

III. Types of Fuse Resistors

Fuse resistors come in various types, each suited for different applications and environments.

A. Wirewound Fuse Resistors

1. Characteristics

Wirewound fuse resistors are made by winding a resistive wire around a ceramic or insulating core. They are known for their high power ratings and excellent thermal stability.

2. Applications

These resistors are commonly used in power supply circuits and high-current applications where reliability is critical.

B. Thick Film Fuse Resistors

1. Characteristics

Thick film fuse resistors are created by applying a thick layer of resistive material onto a substrate. They are compact and can be produced in various shapes and sizes.

2. Applications

These resistors are often found in consumer electronics, such as televisions and computers, where space is limited.

C. Thin Film Fuse Resistors

1. Characteristics

Thin film fuse resistors are made by depositing a thin layer of resistive material onto a substrate. They offer high precision and stability.

2. Applications

These are typically used in high-frequency applications and precision instruments, where accuracy is essential.

D. Comparison of Different Types

When choosing a fuse resistor, it is essential to consider the specific requirements of the application. Wirewound resistors are ideal for high-power applications, while thick and thin film resistors are better suited for compact and precision applications.

IV. Applications of Fuse Resistors

Fuse resistors find applications across various industries due to their unique properties.

A. Use in Power Supply Circuits

In power supply circuits, fuse resistors help manage current levels and protect sensitive components from overcurrent conditions.

B. Role in Overcurrent Protection

Fuse resistors are essential in overcurrent protection systems, ensuring that circuits are safeguarded against excessive current that could lead to failures or hazards.

C. Applications in Consumer Electronics

In consumer electronics, fuse resistors are used to protect devices from power surges and ensure reliable operation.

D. Industrial Applications

In industrial settings, fuse resistors are employed in machinery and equipment to prevent damage from electrical faults.

E. Automotive Applications

In the automotive industry, fuse resistors are used in various electronic systems to protect against overcurrent conditions, ensuring the safety and reliability of vehicles.

V. Advantages of Using Fuse Resistors

Fuse resistors offer several advantages that make them a preferred choice in many applications.

A. Enhanced Safety Features

By combining the functions of a resistor and a fuse, fuse resistors provide enhanced safety features, reducing the risk of electrical fires and component damage.

B. Space Efficiency

Fuse resistors are compact and can be easily integrated into various designs, making them ideal for applications where space is limited.

C. Cost-Effectiveness

While the initial cost may be higher than traditional fuses, the long-term savings from reduced component failures and maintenance make fuse resistors a cost-effective solution.

D. Reliability and Longevity

Fuse resistors are designed for durability and can withstand harsh conditions, ensuring reliable performance over time.

VI. Limitations and Considerations

Despite their advantages, fuse resistors have some limitations that should be considered.

A. Potential Drawbacks

1. Heat Generation

Fuse resistors can generate significant heat during operation, which may require additional cooling measures in some applications.

2. Limited Current Ratings

Each type of fuse resistor has specific current ratings, and exceeding these limits can lead to failure.

B. Factors to Consider When Choosing a Fuse Resistor

1. Application Requirements

It is crucial to assess the specific requirements of the application, including current ratings, voltage levels, and environmental conditions.

2. Environmental Conditions

Consideration of factors such as temperature, humidity, and exposure to chemicals is essential when selecting a fuse resistor.

VII. Installation and Maintenance

Proper installation and maintenance are vital for ensuring the longevity and reliability of fuse resistors.

A. Proper Installation Techniques

Follow manufacturer guidelines for installation, ensuring that the fuse resistor is correctly rated for the application.

B. Maintenance Tips for Longevity

Regular inspections and testing can help identify potential issues before they lead to failures.

C. Troubleshooting Common Issues

Common issues include overheating and failure to interrupt current. Understanding the signs can help in troubleshooting and maintaining the system.

VIII. Future Trends in Fuse Resistor Technology

As technology advances, so do the materials and designs used in fuse resistors.

A. Innovations in Materials and Design

New materials and manufacturing techniques are being developed to enhance the performance and reliability of fuse resistors.

B. The Role of Fuse Resistors in Emerging Technologies

With the rise of electric vehicles, renewable energy systems, and smart electronics, fuse resistors will play a critical role in ensuring safety and reliability.

C. Predictions for Future Developments

Future developments may include more compact designs, higher current ratings, and improved thermal management features.

IX. Conclusion

In conclusion, understanding fuse resistors is essential for anyone involved in electrical engineering or related fields. These components provide critical protection and reliability in various applications, from consumer electronics to industrial machinery. As technology continues to evolve, the importance of fuse resistors will only grow, making it vital for professionals to stay informed about the latest trends and developments.

X. References

A. Suggested Reading Materials

- "Electrical Engineering: Principles and Applications" by Allan R. Hambley

- "Introduction to Electrical Engineering" by John A. G. Brown

B. Relevant Industry Standards and Guidelines

- IEC 60115: Fixed Resistors for Use in Electronic Equipment

- UL 1412: Standard for Fuse Resistors

C. Online Resources for Further Exploration

- IEEE Xplore Digital Library

- Electronics Tutorials and Forums

By exploring the world of fuse resistors, readers can gain valuable insights into their importance and applications, paving the way for further research and learning in this critical area of electrical engineering.

Understanding Fuse Resistors: An In-Depth Guide

I. Introduction

In the world of electrical engineering, safety and reliability are paramount. One component that plays a crucial role in ensuring these qualities is the fuse resistor. This article aims to provide a comprehensive understanding of fuse resistors, their functions, types, applications, advantages, limitations, and future trends. By the end, readers will appreciate the significance of fuse resistors in electrical circuits and their impact on various industries.

II. The Basics of Fuse Resistors

A. What is a Fuse Resistor?

A fuse resistor is a specialized component that combines the functions of a resistor and a fuse. It is designed to limit current flow while also providing overcurrent protection. When the current exceeds a predetermined level, the fuse resistor will "blow," interrupting the circuit and preventing damage to other components.

1. Definition and Function

The primary function of a fuse resistor is to protect sensitive electronic components from excessive current. Unlike traditional fuses, which only serve to interrupt current flow, fuse resistors also provide resistance, allowing them to dissipate heat and manage power levels effectively.

2. Components of a Fuse Resistor

A typical fuse resistor consists of a resistive element, which can be made from various materials, and a protective casing. The resistive element is designed to handle specific current ratings and thermal conditions, while the casing ensures durability and safety.

B. How Fuse Resistors Work

1. The Principle of Operation

Fuse resistors operate on the principle of thermal overload. When the current flowing through the resistor exceeds its rated capacity, the heat generated causes the resistive element to melt or break, effectively interrupting the circuit. This self-resetting feature is what sets fuse resistors apart from traditional fuses.

2. Comparison with Traditional Fuses

Traditional fuses are designed solely to interrupt current flow when it exceeds a certain level. While effective, they do not provide any resistance, which can lead to voltage spikes and potential damage to connected components. Fuse resistors, on the other hand, offer both current limiting and overcurrent protection, making them a more versatile choice in many applications.

III. Types of Fuse Resistors

Fuse resistors come in various types, each suited for different applications and environments.

A. Wirewound Fuse Resistors

1. Characteristics

Wirewound fuse resistors are made by winding a resistive wire around a ceramic or insulating core. They are known for their high power ratings and excellent thermal stability.

2. Applications

These resistors are commonly used in power supply circuits and high-current applications where reliability is critical.

B. Thick Film Fuse Resistors

1. Characteristics

Thick film fuse resistors are created by applying a thick layer of resistive material onto a substrate. They are compact and can be produced in various shapes and sizes.

2. Applications

These resistors are often found in consumer electronics, such as televisions and computers, where space is limited.

C. Thin Film Fuse Resistors

1. Characteristics

Thin film fuse resistors are made by depositing a thin layer of resistive material onto a substrate. They offer high precision and stability.

2. Applications

These are typically used in high-frequency applications and precision instruments, where accuracy is essential.

D. Comparison of Different Types

When choosing a fuse resistor, it is essential to consider the specific requirements of the application. Wirewound resistors are ideal for high-power applications, while thick and thin film resistors are better suited for compact and precision applications.

IV. Applications of Fuse Resistors

Fuse resistors find applications across various industries due to their unique properties.

A. Use in Power Supply Circuits

In power supply circuits, fuse resistors help manage current levels and protect sensitive components from overcurrent conditions.

B. Role in Overcurrent Protection

Fuse resistors are essential in overcurrent protection systems, ensuring that circuits are safeguarded against excessive current that could lead to failures or hazards.

C. Applications in Consumer Electronics

In consumer electronics, fuse resistors are used to protect devices from power surges and ensure reliable operation.

D. Industrial Applications

In industrial settings, fuse resistors are employed in machinery and equipment to prevent damage from electrical faults.

E. Automotive Applications

In the automotive industry, fuse resistors are used in various electronic systems to protect against overcurrent conditions, ensuring the safety and reliability of vehicles.

V. Advantages of Using Fuse Resistors

Fuse resistors offer several advantages that make them a preferred choice in many applications.

A. Enhanced Safety Features

By combining the functions of a resistor and a fuse, fuse resistors provide enhanced safety features, reducing the risk of electrical fires and component damage.

B. Space Efficiency

Fuse resistors are compact and can be easily integrated into various designs, making them ideal for applications where space is limited.

C. Cost-Effectiveness

While the initial cost may be higher than traditional fuses, the long-term savings from reduced component failures and maintenance make fuse resistors a cost-effective solution.

D. Reliability and Longevity

Fuse resistors are designed for durability and can withstand harsh conditions, ensuring reliable performance over time.

VI. Limitations and Considerations

Despite their advantages, fuse resistors have some limitations that should be considered.

A. Potential Drawbacks

1. Heat Generation

Fuse resistors can generate significant heat during operation, which may require additional cooling measures in some applications.

2. Limited Current Ratings

Each type of fuse resistor has specific current ratings, and exceeding these limits can lead to failure.

B. Factors to Consider When Choosing a Fuse Resistor

1. Application Requirements

It is crucial to assess the specific requirements of the application, including current ratings, voltage levels, and environmental conditions.

2. Environmental Conditions

Consideration of factors such as temperature, humidity, and exposure to chemicals is essential when selecting a fuse resistor.

VII. Installation and Maintenance

Proper installation and maintenance are vital for ensuring the longevity and reliability of fuse resistors.

A. Proper Installation Techniques

Follow manufacturer guidelines for installation, ensuring that the fuse resistor is correctly rated for the application.

B. Maintenance Tips for Longevity

Regular inspections and testing can help identify potential issues before they lead to failures.

C. Troubleshooting Common Issues

Common issues include overheating and failure to interrupt current. Understanding the signs can help in troubleshooting and maintaining the system.

VIII. Future Trends in Fuse Resistor Technology

As technology advances, so do the materials and designs used in fuse resistors.

A. Innovations in Materials and Design

New materials and manufacturing techniques are being developed to enhance the performance and reliability of fuse resistors.

B. The Role of Fuse Resistors in Emerging Technologies

With the rise of electric vehicles, renewable energy systems, and smart electronics, fuse resistors will play a critical role in ensuring safety and reliability.

C. Predictions for Future Developments

Future developments may include more compact designs, higher current ratings, and improved thermal management features.

IX. Conclusion

In conclusion, understanding fuse resistors is essential for anyone involved in electrical engineering or related fields. These components provide critical protection and reliability in various applications, from consumer electronics to industrial machinery. As technology continues to evolve, the importance of fuse resistors will only grow, making it vital for professionals to stay informed about the latest trends and developments.

X. References

A. Suggested Reading Materials

- "Electrical Engineering: Principles and Applications" by Allan R. Hambley

- "Introduction to Electrical Engineering" by John A. G. Brown

B. Relevant Industry Standards and Guidelines

- IEC 60115: Fixed Resistors for Use in Electronic Equipment

- UL 1412: Standard for Fuse Resistors

C. Online Resources for Further Exploration

- IEEE Xplore Digital Library

- Electronics Tutorials and Forums

By exploring the world of fuse resistors, readers can gain valuable insights into their importance and applications, paving the way for further research and learning in this critical area of electrical engineering.