Important Product Categories of Wirewound Resistors

I. Introduction

Wirewound resistors are a fundamental component in electronic circuits, playing a crucial role in controlling current flow and voltage levels. These resistors are constructed by winding a wire around a core, typically made of materials like ceramic or fiberglass, which allows for precise resistance values and high power ratings. Their importance cannot be overstated, as they are used in a wide range of applications, from consumer electronics to industrial machinery. This article aims to explore the various product categories of wirewound resistors, their characteristics, applications, and factors influencing their selection.

II. Basic Principles of Wirewound Resistors

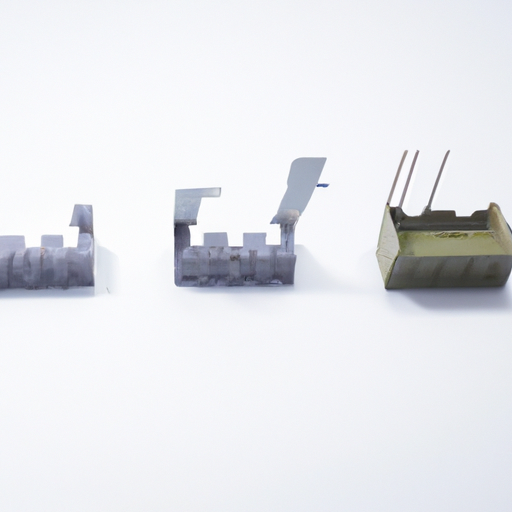

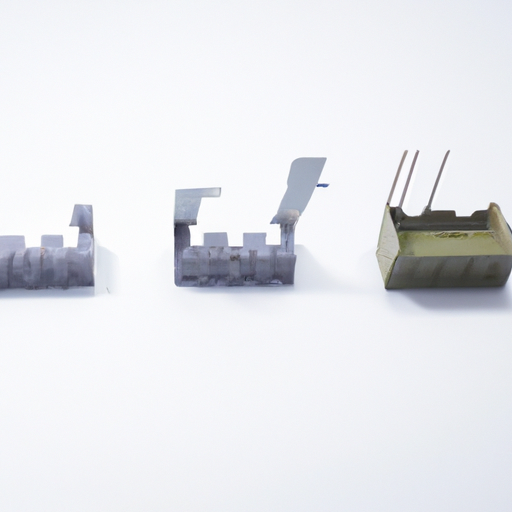

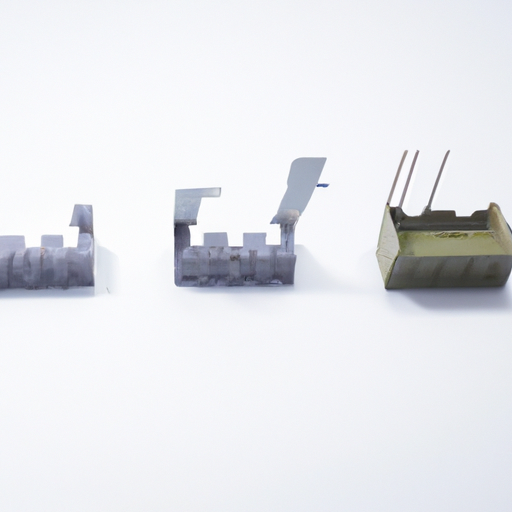

A. Construction and Materials

Wirewound resistors are made from a resistive wire, which can be composed of materials such as nickel-chromium or copper-nickel. The choice of wire material affects the resistor's performance, including its temperature coefficient and stability. The core material, often ceramic or fiberglass, provides structural integrity and thermal management, allowing the resistor to dissipate heat effectively.

B. Working Principle

The operation of wirewound resistors is based on Ohm's Law, which states that the current flowing through a conductor between two points is directly proportional to the voltage across the two points and inversely proportional to the resistance. As current passes through the wire, it generates heat due to its resistance. This heat must be managed to prevent damage to the resistor and surrounding components, making thermal management a critical aspect of wirewound resistor design.

III. Key Product Categories of Wirewound Resistors

A. Fixed Wirewound Resistors

Fixed wirewound resistors are the most common type, providing a specific resistance value that does not change. They are widely used in applications where precise resistance is required, such as in voltage dividers and current limiting circuits.

**Advantages and Disadvantages:**

The primary advantage of fixed wirewound resistors is their stability and accuracy. However, they lack flexibility, as their resistance cannot be adjusted once manufactured.

**Common Specifications:**

These resistors come in various resistance values, typically ranging from a few ohms to several megaohms, with power ratings that can exceed 100 watts.

B. Adjustable Wirewound Resistors (Potentiometers)

Adjustable wirewound resistors, commonly known as potentiometers, allow users to change the resistance value as needed. They are essential in applications requiring variable resistance, such as volume controls in audio equipment.

**Types of Adjustable Wirewound Resistors:**

1. **Trimming Potentiometers:** Used for fine-tuning circuits during manufacturing or calibration.

2. **Multi-Turn Potentiometers:** Allow for precise adjustments over multiple turns, ideal for applications requiring high accuracy.

**Advantages and Disadvantages:**

The main advantage of adjustable wirewound resistors is their versatility. However, they may be less stable than fixed resistors and can be more susceptible to wear over time.

C. High-Precision Wirewound Resistors

High-precision wirewound resistors are designed for applications that require exceptional accuracy and stability. They are often used in measurement and calibration equipment.

**Tolerance Levels and Temperature Coefficients:**

These resistors typically have tolerance levels as low as 0.01% and temperature coefficients of resistance (TCR) that ensure minimal drift with temperature changes.

**Use in Measurement and Calibration:**

Their high precision makes them ideal for use in laboratory settings and high-end instrumentation, where accuracy is paramount.

D. High-Power Wirewound Resistors

High-power wirewound resistors are built to handle significant amounts of power, making them suitable for applications in power electronics and industrial machinery.

**Power Ratings and Heat Dissipation:**

These resistors can handle power ratings exceeding 1,000 watts, and their design includes features for effective heat dissipation, such as larger surface areas and heat sinks.

**Use in Power Electronics and Industrial Applications:**

They are commonly used in braking systems, load banks, and other applications where high power and thermal management are critical.

E. Low-Value Wirewound Resistors

Low-value wirewound resistors are typically used in current sensing and shunt applications. They provide low resistance values, often in the milliohm range, allowing for accurate current measurement.

**Importance in Current Sensing and Shunt Applications:**

These resistors are crucial in applications where monitoring current flow is necessary, such as in power supplies and battery management systems.

**Design Considerations:**

When designing low-value wirewound resistors, factors such as inductance and thermal performance are critical to ensure accurate readings and reliability.

F. Specialty Wirewound Resistors

Specialty wirewound resistors cater to niche applications that require specific characteristics not found in standard resistors.

**Types of Specialty Resistors:**

1. **High-Voltage Wirewound Resistors:** Designed to withstand high voltage levels, making them suitable for applications in power distribution and electrical testing.

2. **High-Frequency Wirewound Resistors:** Engineered to minimize inductance and maintain performance at high frequencies, ideal for RF applications.

**Niche Applications and Benefits:**

These specialty resistors provide tailored solutions for unique challenges in various industries, enhancing performance and reliability.

IV. Factors Influencing the Selection of Wirewound Resistors

When selecting wirewound resistors, several factors must be considered to ensure optimal performance in a given application.

A. Resistance Value and Tolerance

The required resistance value and tolerance level are critical in determining the appropriate resistor for a specific application. High-precision applications may necessitate tighter tolerances.

B. Power Rating and Thermal Management

Understanding the power rating is essential to prevent overheating and ensure the resistor can handle the expected load. Effective thermal management strategies, such as heat sinks or proper ventilation, may be necessary.

C. Environmental Considerations

Factors such as temperature, humidity, and exposure to chemicals can affect resistor performance. Selecting resistors with appropriate environmental ratings is crucial for long-term reliability.

D. Application-Specific Requirements

Different applications may have unique requirements regarding size, footprint, and mounting options. Ensuring compatibility with the overall design is essential for successful integration.

V. Applications of Wirewound Resistors

Wirewound resistors find applications across various industries, showcasing their versatility and reliability.

A. Consumer Electronics

In consumer electronics, wirewound resistors are used in devices such as televisions, audio equipment, and computers, where precise control of current and voltage is essential.

B. Industrial Equipment

Industrial machinery relies on wirewound resistors for functions such as motor control, load testing, and power regulation, ensuring efficient operation and safety.

C. Automotive Applications

In the automotive sector, wirewound resistors are used in electronic control units, braking systems, and battery management systems, contributing to vehicle performance and safety.

D. Medical Devices

Medical devices, including diagnostic equipment and monitoring systems, utilize wirewound resistors for their accuracy and reliability, ensuring patient safety and effective treatment.

E. Telecommunications

In telecommunications, wirewound resistors are employed in signal processing and transmission equipment, where stability and performance are critical for maintaining communication quality.

VI. Conclusion

Wirewound resistors are indispensable components in modern electronics, offering a range of product categories tailored to meet diverse application needs. From fixed and adjustable resistors to high-precision and specialty options, each category serves a unique purpose, ensuring reliability and performance across various industries. As technology continues to evolve, advancements in wirewound resistor design and materials will likely lead to even greater capabilities and applications, solidifying their role in the future of electronics.

VII. References

1. Academic journals and articles on resistor technology and applications.

2. Industry standards and guidelines for electronic components.

3. Manufacturer specifications and datasheets for wirewound resistors.

This comprehensive overview of wirewound resistors highlights their importance, various product categories, and the factors influencing their selection, providing valuable insights for engineers and designers in the field.

Important Product Categories of Wirewound Resistors

I. Introduction

Wirewound resistors are a fundamental component in electronic circuits, playing a crucial role in controlling current flow and voltage levels. These resistors are constructed by winding a wire around a core, typically made of materials like ceramic or fiberglass, which allows for precise resistance values and high power ratings. Their importance cannot be overstated, as they are used in a wide range of applications, from consumer electronics to industrial machinery. This article aims to explore the various product categories of wirewound resistors, their characteristics, applications, and factors influencing their selection.

II. Basic Principles of Wirewound Resistors

A. Construction and Materials

Wirewound resistors are made from a resistive wire, which can be composed of materials such as nickel-chromium or copper-nickel. The choice of wire material affects the resistor's performance, including its temperature coefficient and stability. The core material, often ceramic or fiberglass, provides structural integrity and thermal management, allowing the resistor to dissipate heat effectively.

B. Working Principle

The operation of wirewound resistors is based on Ohm's Law, which states that the current flowing through a conductor between two points is directly proportional to the voltage across the two points and inversely proportional to the resistance. As current passes through the wire, it generates heat due to its resistance. This heat must be managed to prevent damage to the resistor and surrounding components, making thermal management a critical aspect of wirewound resistor design.

III. Key Product Categories of Wirewound Resistors

A. Fixed Wirewound Resistors

Fixed wirewound resistors are the most common type, providing a specific resistance value that does not change. They are widely used in applications where precise resistance is required, such as in voltage dividers and current limiting circuits.

**Advantages and Disadvantages:**

The primary advantage of fixed wirewound resistors is their stability and accuracy. However, they lack flexibility, as their resistance cannot be adjusted once manufactured.

**Common Specifications:**

These resistors come in various resistance values, typically ranging from a few ohms to several megaohms, with power ratings that can exceed 100 watts.

B. Adjustable Wirewound Resistors (Potentiometers)

Adjustable wirewound resistors, commonly known as potentiometers, allow users to change the resistance value as needed. They are essential in applications requiring variable resistance, such as volume controls in audio equipment.

**Types of Adjustable Wirewound Resistors:**

1. **Trimming Potentiometers:** Used for fine-tuning circuits during manufacturing or calibration.

2. **Multi-Turn Potentiometers:** Allow for precise adjustments over multiple turns, ideal for applications requiring high accuracy.

**Advantages and Disadvantages:**

The main advantage of adjustable wirewound resistors is their versatility. However, they may be less stable than fixed resistors and can be more susceptible to wear over time.

C. High-Precision Wirewound Resistors

High-precision wirewound resistors are designed for applications that require exceptional accuracy and stability. They are often used in measurement and calibration equipment.

**Tolerance Levels and Temperature Coefficients:**

These resistors typically have tolerance levels as low as 0.01% and temperature coefficients of resistance (TCR) that ensure minimal drift with temperature changes.

**Use in Measurement and Calibration:**

Their high precision makes them ideal for use in laboratory settings and high-end instrumentation, where accuracy is paramount.

D. High-Power Wirewound Resistors

High-power wirewound resistors are built to handle significant amounts of power, making them suitable for applications in power electronics and industrial machinery.

**Power Ratings and Heat Dissipation:**

These resistors can handle power ratings exceeding 1,000 watts, and their design includes features for effective heat dissipation, such as larger surface areas and heat sinks.

**Use in Power Electronics and Industrial Applications:**

They are commonly used in braking systems, load banks, and other applications where high power and thermal management are critical.

E. Low-Value Wirewound Resistors

Low-value wirewound resistors are typically used in current sensing and shunt applications. They provide low resistance values, often in the milliohm range, allowing for accurate current measurement.

**Importance in Current Sensing and Shunt Applications:**

These resistors are crucial in applications where monitoring current flow is necessary, such as in power supplies and battery management systems.

**Design Considerations:**

When designing low-value wirewound resistors, factors such as inductance and thermal performance are critical to ensure accurate readings and reliability.

F. Specialty Wirewound Resistors

Specialty wirewound resistors cater to niche applications that require specific characteristics not found in standard resistors.

**Types of Specialty Resistors:**

1. **High-Voltage Wirewound Resistors:** Designed to withstand high voltage levels, making them suitable for applications in power distribution and electrical testing.

2. **High-Frequency Wirewound Resistors:** Engineered to minimize inductance and maintain performance at high frequencies, ideal for RF applications.

**Niche Applications and Benefits:**

These specialty resistors provide tailored solutions for unique challenges in various industries, enhancing performance and reliability.

IV. Factors Influencing the Selection of Wirewound Resistors

When selecting wirewound resistors, several factors must be considered to ensure optimal performance in a given application.

A. Resistance Value and Tolerance

The required resistance value and tolerance level are critical in determining the appropriate resistor for a specific application. High-precision applications may necessitate tighter tolerances.

B. Power Rating and Thermal Management

Understanding the power rating is essential to prevent overheating and ensure the resistor can handle the expected load. Effective thermal management strategies, such as heat sinks or proper ventilation, may be necessary.

C. Environmental Considerations

Factors such as temperature, humidity, and exposure to chemicals can affect resistor performance. Selecting resistors with appropriate environmental ratings is crucial for long-term reliability.

D. Application-Specific Requirements

Different applications may have unique requirements regarding size, footprint, and mounting options. Ensuring compatibility with the overall design is essential for successful integration.

V. Applications of Wirewound Resistors

Wirewound resistors find applications across various industries, showcasing their versatility and reliability.

A. Consumer Electronics

In consumer electronics, wirewound resistors are used in devices such as televisions, audio equipment, and computers, where precise control of current and voltage is essential.

B. Industrial Equipment

Industrial machinery relies on wirewound resistors for functions such as motor control, load testing, and power regulation, ensuring efficient operation and safety.

C. Automotive Applications

In the automotive sector, wirewound resistors are used in electronic control units, braking systems, and battery management systems, contributing to vehicle performance and safety.

D. Medical Devices

Medical devices, including diagnostic equipment and monitoring systems, utilize wirewound resistors for their accuracy and reliability, ensuring patient safety and effective treatment.

E. Telecommunications

In telecommunications, wirewound resistors are employed in signal processing and transmission equipment, where stability and performance are critical for maintaining communication quality.

VI. Conclusion

Wirewound resistors are indispensable components in modern electronics, offering a range of product categories tailored to meet diverse application needs. From fixed and adjustable resistors to high-precision and specialty options, each category serves a unique purpose, ensuring reliability and performance across various industries. As technology continues to evolve, advancements in wirewound resistor design and materials will likely lead to even greater capabilities and applications, solidifying their role in the future of electronics.

VII. References

1. Academic journals and articles on resistor technology and applications.

2. Industry standards and guidelines for electronic components.

3. Manufacturer specifications and datasheets for wirewound resistors.

This comprehensive overview of wirewound resistors highlights their importance, various product categories, and the factors influencing their selection, providing valuable insights for engineers and designers in the field.